Design & Drawings

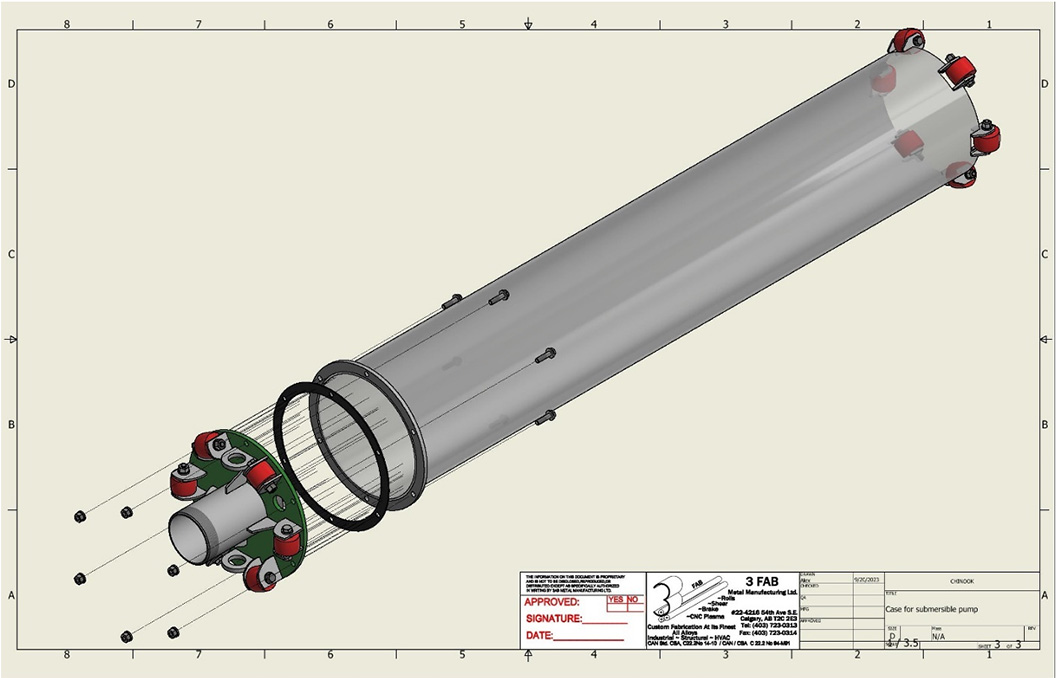

Design & Shop Drawings

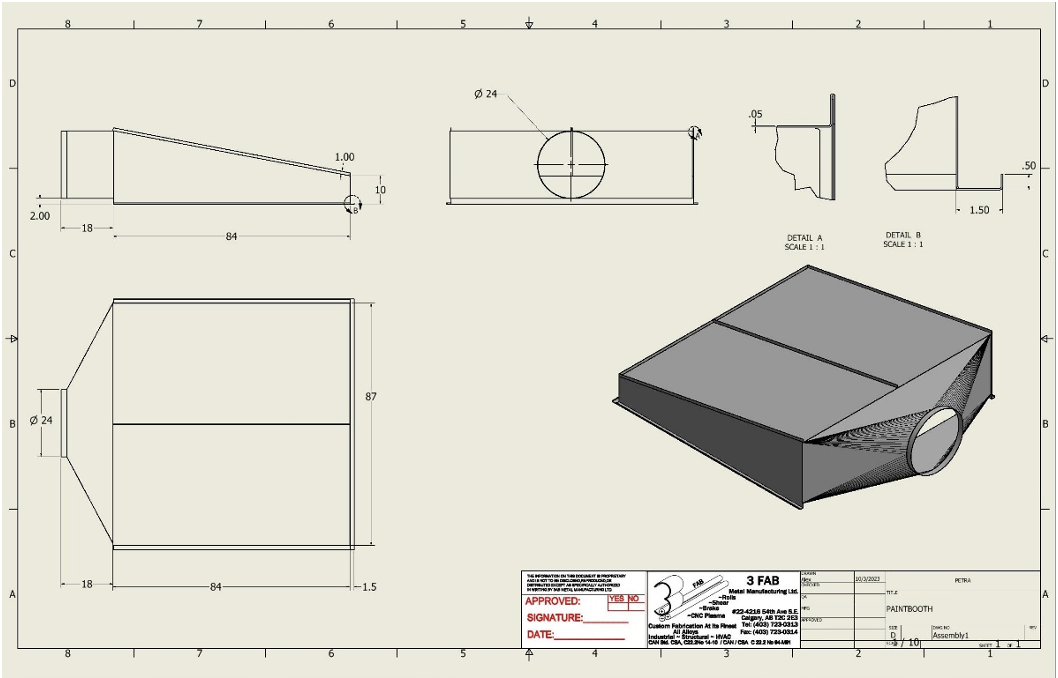

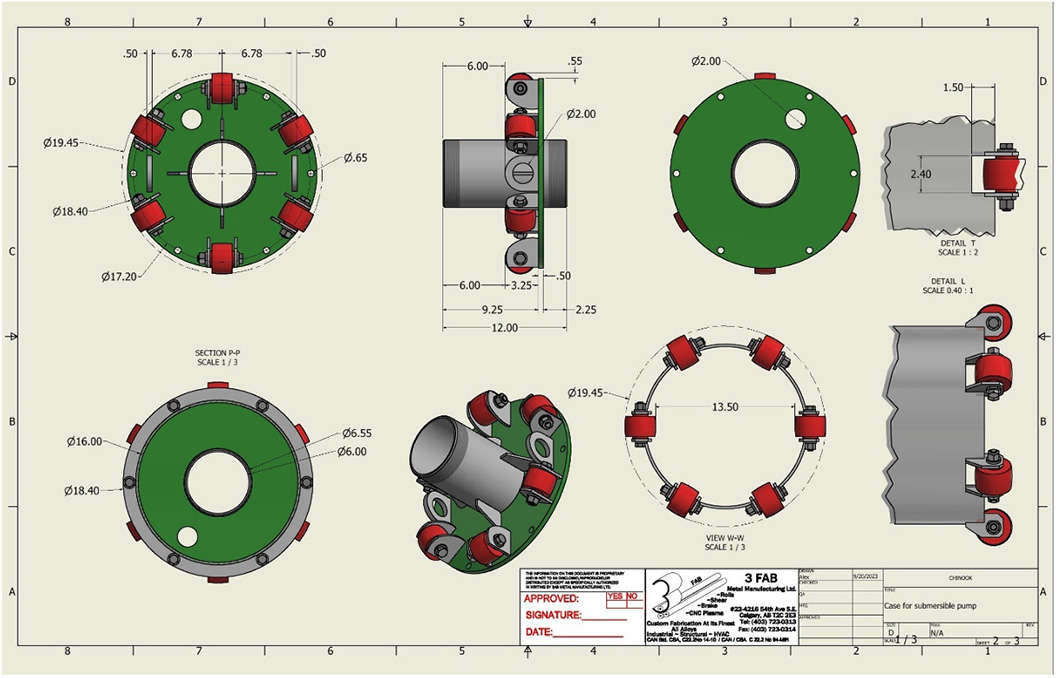

We provide a range of design and shop drawings that detail various aspects of the metal products we manufacture. These drawings serve as essential documentation for fabrication, assembly, and installation processes. Here are some common types of design and shop drawings that our shop provides:

Detail Drawings:

- These provide comprehensive information about specific components, including dimensions, material specifications, and manufacturing processes.

Assembly Drawings:

- Show how individual parts fit together to form a complete product. This includes welds, fasteners, and other connections.

Cutting and Bending Diagrams:

- Illustrate the shapes and dimensions of metal pieces before and after cutting and bending operations.

Welding Diagrams:

- Indicate the type, size, and location of welds needed to join metal components.

Material Specifications:

- Detail the specific types, grades, and dimensions of materials to be used.

Finishing and Coating Instructions:

- Specify any surface treatments, coatings, or finishes that need to be applied to the metal.

Machining and Tooling Diagrams:

- Provide information on machining operations, such as drilling, milling, and threading.

Hardware and Fastener Lists:

- Itemize the types and quantities of fasteners, bolts, nuts, and other hardware needed for assembly.

Bill of Materials (BOM):

- A comprehensive list of all components, including their part numbers, descriptions, and quantities.

Punching and Piercing Diagrams:

- Show the locations and dimensions of holes, slots, or other openings to be made in the metal.

Forming and Rolling Instructions:

- Provide details on how the metal will be shaped, bent, or rolled to achieve the desired form.

Tolerance and Quality Standards:

- Specify acceptable levels of deviation from specified dimensions to ensure quality control.

Alignment and Installation Guidelines:

- Offer instructions for aligning and installing metal components correctly.

Safety and Compliance Information:

- Include any safety considerations, regulatory compliance, or industry standards that need to be followed.

Stamped Engineered Drawings

- Once a drawing meets all requirements and standards, a licensed engineer may be needed to a fixed their official seal or stamp on the drawings, indicating that they have been reviewed and approved.

Customized Solutions for Specific Projects:

- Provide drawings tailored to the unique requirements of individual projects.

These drawings are crucial for ensuring accuracy and consistency in the manufacturing process, as well as for facilitating effective communication between designers, fabricators, and installers. They also serve as a reference for quality assurance and compliance with industry standards and regulations.

How can we help?

With decades of experience, our dedicated team and state of the art manufacturing, 3FAB will design and manufacture a solution to solve your most challenging problems.

Contact us today by email at sales@3fab.ca or by phone at 403-723-0313

Contact Us

3FAB Metal Manufacturing Ltd.

Bay 22, 4216 – 54th Ave S.E.

Calgary, Alberta T2C 2E3

Phone: (403) 723-0313

Fax: (403) 723-0314

Email: sales@3fab.ca

Business Hours

Monday to Thursday

8 am–4 pm

Friday 8 am–12 noon

Saturday Closed

Sunday Closed

Closed all statutory holidays